Our Verdict

The Anycubic Kobra Go is a great option for those looking for a lower-cost FDM printer. It has some neat features for the price point and, once the time is invested to build and calibrate, produces good results.

For

- Self-levelling is a one-touch operation

- Fast printing is always a plus

- Generous build volume

Against

- DIY process not for some user’s tastes

- Some calibration needed to get the best results.

Why you can trust Creative Bloq

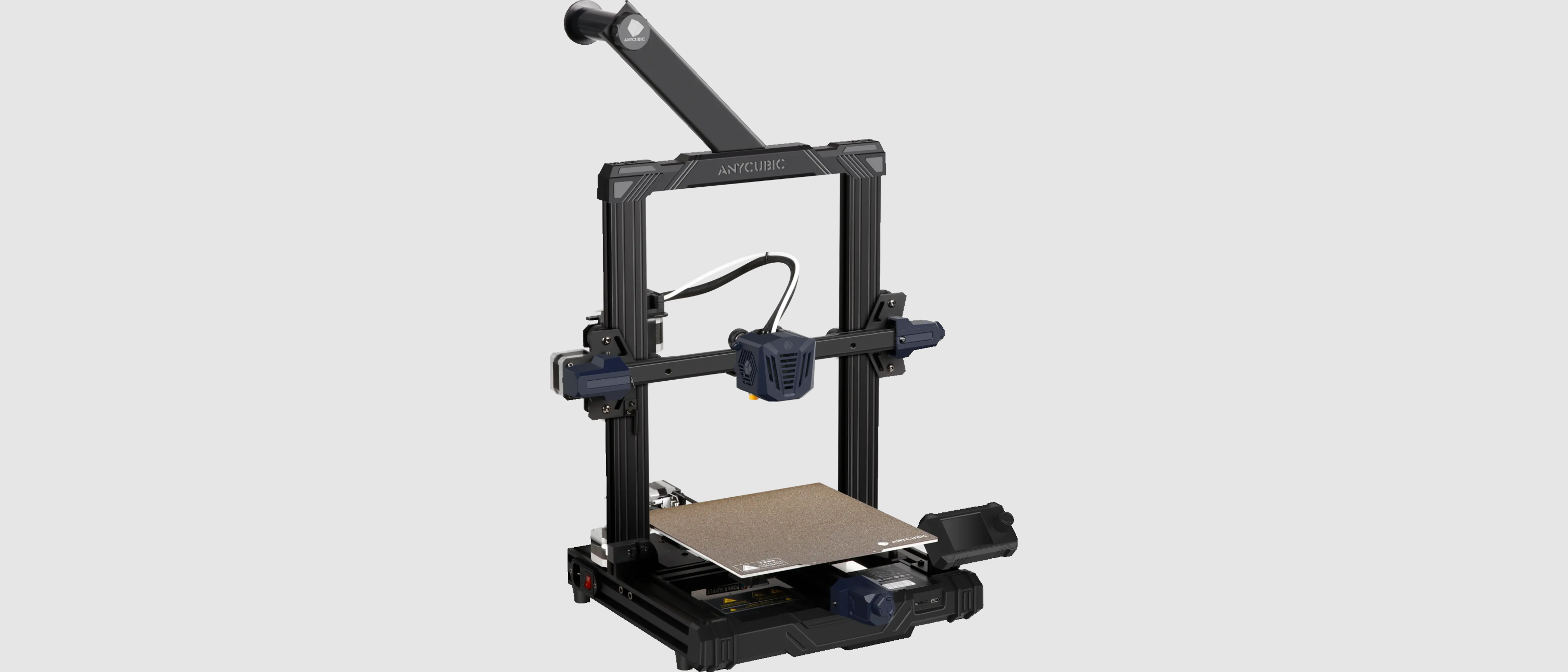

Anycubic Kobra Go comes from a respected 3D printer manufacturer that has built a reputation for quality 3D printers at reasonable prices, but the market is a busy one and finding a way to compete is an ongoing challenge. With the Kobra Go, it looks like the company is tackling the lower end of this market but offering some features that feel a cut above what you’d usually consider a budget option.

Anycubic already has several products among the best 3D printers on the market, but can the Kobra Go stack up among them? Let's find out.

Anycubic Kobra Go: Features

The Kobra Go feels like a quality machine, constructed from nice materials. It’s sturdy and rugged but with less of an industrial feel than some of its competitors. What surprises there is that the Kobra is a DIY device. There’s a certain amount of assembly involved. Not huge amounts, and the process can be completed in 20 minutes or so, but enough to give a good level of familiarity with how the Kobra works and is put together.

This means certain features come to the fore, like the sprung metal print bed, which makes print removal a doddle. This bed attaches magnetically to the self-levelling platform, operated by a single button. This simple operation belies the 25-point levelling mechanism, which really aids in print quality.

Then there’s the big one. The hot end and extruder are separate units, making for less backlash and inertial issues, so the printer can operate faster and more accurately, at up to 100mm per second. Not bad but also pretty useful, considering the large build volume of 200 x 200 x 250mm.

Another feature that Anycubic is making a big deal of is the single knob belt tensioner and rightly so. It always feels like an unnecessary faff having to dig out the right tool when it really should be a simple hand control. It’s a small peeve but one that I’m glad has been countered here.

Anycubic Kobra Go: Sensors

One of the biggest keys to good print results and minimised failures is having a level bed. The Kobra Go has 25 points for the built-in levelling system, which is operated by a single button.

Daily design news, reviews, how-tos and more, as picked by the editors.

On top of this, the Kobra Go has a sensor to prevent print fails in case of pauses. So if you need to load a new reel it won't mean restarting the print job.

Anycubic Kobra Go: Performance

None of these features matter if the print quality isn’t good enough though, so it’s great to see some respectable results coming off the Kobra Go’s plate. After a little calibration, the Kobra produces accurate results, even at higher speeds and this carries across no matter what filament is used, from ABS and PLA to trickier materials like PETG. There didn’t seem to be a drop-off near the edges which can be seen in other low-end printers.

Of course, this isn’t going to be producing as fine detailed models as a resin printer but it isn’t meant to. Instead, the Kobra compliments a resin printer, where faster, cheaper prints are needed. Perfect for rapid prototyping forms and ideas, or for churning out large-scale cosplay items or wargames terrain.

Should you buy the Anycubic Kobra Go?

The Kobra Go is a great option for those looking for a lower-cost FDM printer. It has some neat features for the price point and, once the time is invested to build and calibrate, produces good results.

out of 10

The Anycubic Kobra Go is a great option for those looking for a lower-cost FDM printer. It has some neat features for the price point and, once the time is invested to build and calibrate, produces good results.

Rob Redman is the editor of ImagineFX magazines and former editor of 3D World magazine. Rob has a background in animation, visual effects, and photography.