Our Verdict

For those looking for the finest detail results, who want a larger build volume and want results fast, the Saturn 4 Ultra 16K is a real winner. It provides all of the above, as well as some features that help keep results consistent and easy to manage. One for any shortlist.

For

- Excellent design and build

- Larger build volume

- Easy for beginners

- Top notch print quality

Against

- Slightly messy post processing

Why you can trust Creative Bloq

The available options for 3D printers is growing, with developers adding new models in quick succession, each promising to be faster and more accurate than the last. Most commonly these are incremental improvements but sometimes a machine will arrive that is considerably better than the previous iteration. Elegoo’s Mars range is one such resin printer but is limited in build volume. If you are looking at larger scale projects then it may be that their Saturn range is for you – and the release of the Saturn 4 Ultra 16K, promises not just a larger build but finer detail, high speeds and a number of other features to help you get the best 3D prints.

I’ve been using and testing 3D printers of all kinds for over a decade now and I’m always interested to check out the latest developments. I loved the Mars 5, so was curious to see if the Saturn hit all the same marks as the best 3D printers.

Elegoo Saturn 4 Ultra 16K: What's in the box?

Resin printers tend to need less setup than FDM printers and this is true of the Saturn, which ships ready to go, other than adding the build platform to the Y axis.

It ships with a selection of tools, including gloves, resin filters and scrapers for removing projects from the platform.

There’s also a plastic bib used when removing a finished job. More on that later.

Added to that, there's the resin vat, which is attached in place. What's more, this vat is heated but that requires no extra steps or hardware.

Unlike some resin printers there is no onboard filter for fumes but there is a removable section on the rear, which can be used for attaching extraction. No adapter is included but you can get the stl to print one, should you need it. If you plan to use this in the home I would recommend doing this, as the fumes can be pretty noxious.

Daily design news, reviews, how-tos and more, as picked by the editors.

Setup and build quality

Set up is a simple process. The vat needs to be removed, so the screen protection film can be removed. Once that is bolted back down, using the two large thumb screws, the build platform can be attached. This is done with a single large lever, which engages nicely and is a much more elegant solution than the screws or thumbwheels seen on other devices.

Next up is to power on the Saturn and let it run through its initial start up process, including setting wifi connections. The screen shows each step of the internal checks, which take a few minutes, then it’s ready for use.

As you can see in the photo, it is a larger machine than the Mars but not massively so, although the build volume is significantly bigger at 220 x 118 x 220mm. Another big difference is the lid. So many resin printers use lift off lids. They function fine but it can be a bit of a faff finding somewhere to put them while you deal with the printer, so it’s really nice to see the Saturn with its hinged lid. You will need a little space behind the machine, as the hinge isn’t at the very top but it’s only a few inches, so not a problem.

The overall build quality of the Saturn is excellent, made mostly from metal, with the plastic cover. All components fit well, with a great level of finish.

There are a few features on offer here that are still not the norm on resin printers, the main two being a smart AI camera which can both look for printer failures as well as record timelapses. I’ve seen other printers with a camera and they can be hit and miss. Partly due to the lack of light inside, as well as the placement which isn’t always best suited to produce good results. The Saturn’s on the other hand is well placed and has a light, making sure you get nice timelapses and the AI can better interpret what it sees.

The other is a heated vat. Temperature is a crucial factor for consistent, successful results and it’s great to see a heated vat/tank. It appears to be a fixed temperature but any help is welcome, so thumbs up to Elegoo for including that here.

The only part of the whole system that doesn’t get full marks is the resin bib/shield, which has to be placed around the vat when removing a finished job. This is to prevent resin from getting into the interior of the printer. It’s great that it’s included but it is made from the flimsiest cheap plastic. It functions just fine but feels like some cost cutting was made. That said it’s a small nitpick and could save your machine.

The reason for needing the bib in the first place is because, unlike most printers, the vat itself tips between layers. This is done to aid speed but does mean there’s a small gap between that resin could get into, possibly causing havoc with the inner components. I’ve run many prints through this and had no issues so, cheap though it is, the bib does a good job.

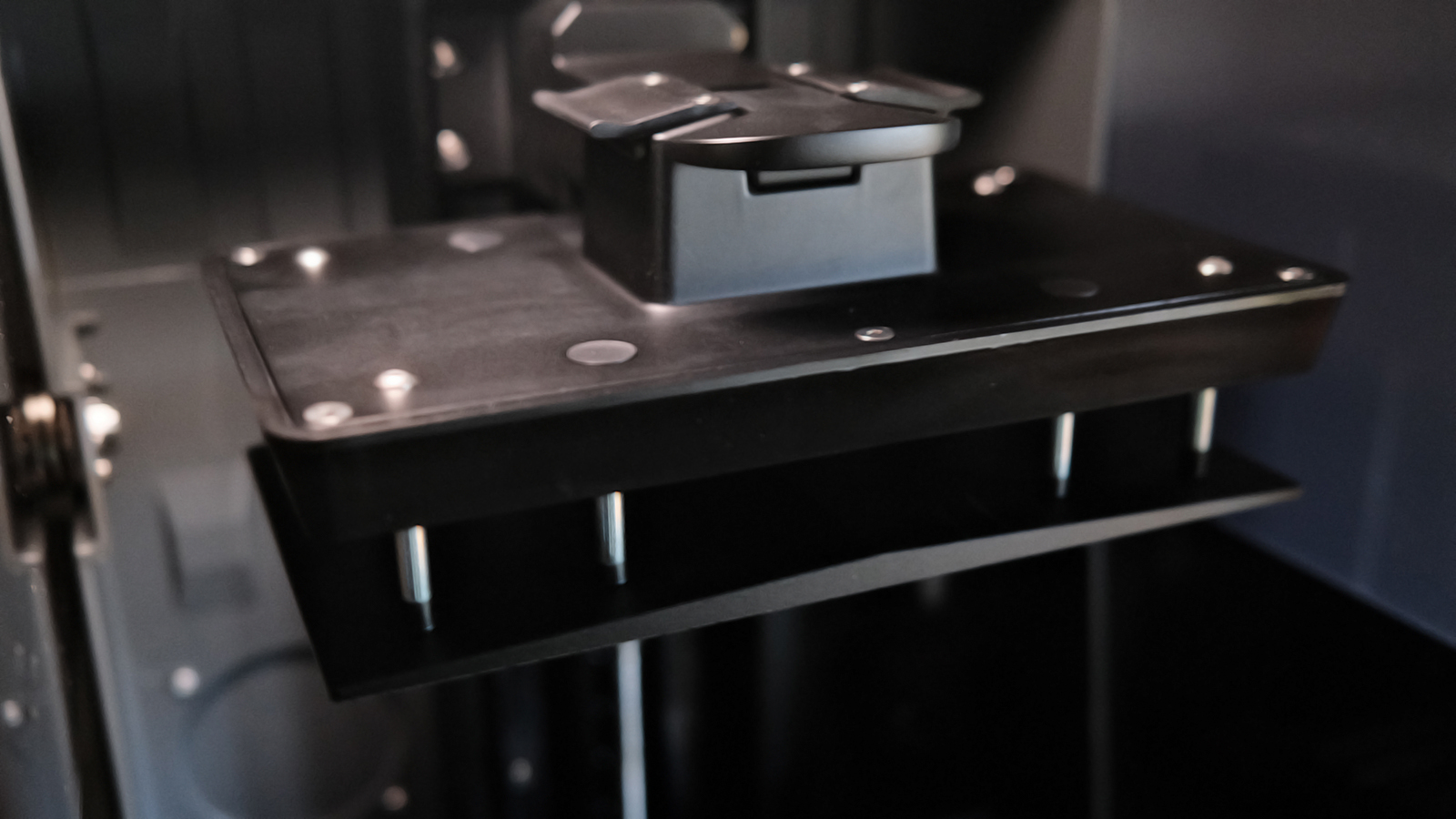

The build platform is a ‘self levelling’ one, which is partly true. No adjustments are made or levelling calibrations done. However it is a two part piece, with the actual platform attached via springs, so that it naturally levels out once it hits the vat or layer, keeping it level. While this does make cleaning the platform harder (as you need to get between the two layers and springs) the system seems to work well and caused no issues.

Elegoo Saturn 4 Ultra 16K: Performance

In testing a new 3D printer I usually run a few standard models to see how it runs without any tweaks to settings and did that here, using a benchy and Siraya’s V5 test model. I sliced these using the Elegoo software and also tested using Lychee.

Now, it’s likely to assume that a higher resolution will yield more defined results and, seeing as the Saturn is a 16K printer, you’d think that you couldn’t get any more fidelity but it’s not as clear cut as that.

You do need to take into account things like layer thickness and the resin being used. Elegoo sent me some of their 8K standard resin, which I’ve used many times before with excellent results. I actually found that with the initial settings results were actually slightly softer than when using the Mars 5 but after some adjusting of settings there was almost no difference. This might be due to the fact the Mars is already and excellent machine with very good detail. It could also be down to the resin but I had hoped to see the Saturn show signs of even higher detail. That isn’t to say it doesn’t produces excellent results. It does, just not any better than the Mars. Actually that’s only partially true. Details don’t seem any crisper but surfaces do appear smoother. The Saturn has zero visible layer lines, which can be attributed to a combo of the resolution, peeling motion of the tank and

That said, the biggest draw of the Saturn is a double whammy of build volume and speed. You can produce significantly bigger prints with the Saturn, making this excellent for thighs like statues, wargames terrain and product concepts, amongst others.

What really sells it though is the speed. That tipping resin tank is part of the process designed to speed up a project and it does a great job. At first it’s slightly unnerving seeing it dip but it’s well worth it. Another benefit of this is that rather than pulling the build platform up uniformly from the just cured layer, it rather peels it back. This feels like it is putting less stress on the print and possibly reduces the risk of failed prints. However I’ve never suffered print failures on Elegoo’s resin printers, so this is a hunch rather than a measurable fact.

As mentioned before, the ‘self-levelling’ platform works really well but it is a faff to clean. The plastic bib works to prevent damage to the printer but there’s still the job of removing resin from between the two sections. I found the best way is to lift it out and put it in my Mercury wash and cure, using a tattoo artist squirty bottle filled with IPA, to wash off the platform before removing the print job.

This little extra post work is more than worth it though. The quality of the prints is excellent and the speed increase is pretty substantial.

Elegoo has also included a smart vat heater in the Saturn too. I’m not sure how smart it is but it seems effective. The temperature is fixed at 30C and although hard to quantify I’d say it’s a feature worth having, as temperature is important to print success and consistency is important and I’d like to see this on more printers.

The AI camera is hard to judge. I had no print failures while testing, so unsure of how well it can sense problems but it’s very good for timelapses, thanks to the aid of the built in light. The Saturn’s cover is a dark grey so external light won’t be enough to illuminate the build volume, something I’ve noticed in other devices. It’s good to see Elegoo counter this issue. I’m kind of keen to have a failed print to see if the AI can report it. Elegoo doesn't say it pauses the print, only alerting the issue, which is probably for the best, as I’d rather make that decision myself and it’s possible to monitor the camera output remotely at any time.

All in all the Saturn is a fantastic resin printer and one that would suit anybody looking to print larger projects, be they beginner or advanced user. In fact this would make a perfect beginner resin printer. Elegoo holds the hand really well from the off but you can drill down and tweak everything once you are more confident.

Elegoo Saturn 4 Ultra 16K: Who is it for?

Anybody looking for large and fast, high quality results

Elegoo Saturn 4 Ultra 16K: Buy it if

- You can easily deal with resin post processing

- You want exceptional quality

Elegoo Saturn 4 Ultra 16K: Don't buy it if

- If smaller prints are all you need

out of 10

For those looking for the finest detail results, who want a larger build volume and want results fast, the Saturn 4 Ultra 16K is a real winner. It provides all of the above, as well as some features that help keep results consistent and easy to manage. One for any shortlist.

Rob Redman is the editor of ImagineFX magazines and former editor of 3D World magazine. Rob has a background in animation, visual effects, and photography.

You must confirm your public display name before commenting

Please logout and then login again, you will then be prompted to enter your display name.