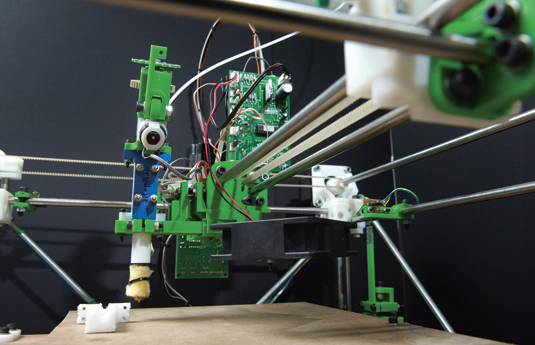

5 ways to make your 3D printing cheaper and more reliable

Toy modeller Steve Talkowski shares his hints and tips for getting better 3D prints.

Daily design news, reviews, how-tos and more, as picked by the editors.

You are now subscribed

Your newsletter sign-up was successful

Want to add more newsletters?

Five times a week

CreativeBloq

Your daily dose of creative inspiration: unmissable art, design and tech news, reviews, expert commentary and buying advice.

Once a week

By Design

The design newsletter from Creative Bloq, bringing you the latest news and inspiration from the worlds of graphic design, branding, typography and more.

Once a week

State of the Art

Our digital art newsletter is your go-to source for the latest news, trends, and inspiration from the worlds of art, illustration, 3D modelling, game design, animation, and beyond.

Seasonal (around events)

Brand Impact Awards

Make an impression. Sign up to learn more about this prestigious award scheme, which celebrates the best of branding.

It's understandable. You've finished your design and you want to 3D print the model as soon as possible.

The chances are however, if you just hit the print button and hope, you'll be heading for disappointment. That's because there's a real knack to 3D printing.

Here are our five top tips for more successful 3D printing. They're short and to the point, and if you follow them, you'll find your models will stand straight and look beautiful.

01. Plan your print

Plan ahead and identify what your final output needs to be. If you’re doing a character that will be cast in resin, you'll want to segment your pieces with an interlocking key system.

02. Use supports

If you plan on printing out a figure as one solid piece, you'll want to consider placing supports at overhang areas. Some slicing/preference software will do this automatically. Optionally, you can make your own supports and taper them down at the tips where they will attach to the geometry.

03. Hollow the pieces

It's essential to hollow out your pieces to save on material cost. Personally, I love using ZBrush and the Create Shell command (via DynaMesh) to subtract a shape used as an opening while hollowing out.

04. Know your materials

Learn the tolerances of the various materials used, especially when creating interlocking posts. It's better to err on the larger side, because you can always sand or trim down the piece afterwards. If it's too small, I'll use something thin like magic tape to bulk a post back up for a tighter fit.

Daily design news, reviews, how-tos and more, as picked by the editors.

05. Poly counts and files

You'll have to keep your poly count relatively low when saving as an .stl or .obj file. Again, ZBrush is your friend, especially the Decimation Master plug-in. You can take a multi-million poly piece down to 10-20k and retain the detail prior to .stl export.

Words: Steve Talkowski

Steve Talkowski is a character designer and animation director from Los Angeles. This article originally appeared in 3D World issue 183.

The Creative Bloq team is made up of a group of art and design enthusiasts, and has changed and evolved since Creative Bloq began back in 2012. The current website team consists of eight full-time members of staff: Editor Georgia Coggan, Deputy Editor Rosie Hilder, Ecommerce Editor Beren Neale, Senior News Editor Daniel Piper, Editor, Digital Art and 3D Ian Dean, Tech Reviews Editor Erlingur Einarsson, Ecommerce Writer Beth Nicholls and Staff Writer Natalie Fear, as well as a roster of freelancers from around the world. The ImagineFX magazine team also pitch in, ensuring that content from leading digital art publication ImagineFX is represented on Creative Bloq.