Discover 3D printing

The tech behind 3D printing has been around for over 25 years, but it’s only recently become affordable to individuals – with some fascinating creative results

Daily design news, reviews, how-tos and more, as picked by the editors.

You are now subscribed

Your newsletter sign-up was successful

Want to add more newsletters?

Five times a week

CreativeBloq

Your daily dose of creative inspiration: unmissable art, design and tech news, reviews, expert commentary and buying advice.

Once a week

By Design

The design newsletter from Creative Bloq, bringing you the latest news and inspiration from the worlds of graphic design, branding, typography and more.

Once a week

State of the Art

Our digital art newsletter is your go-to source for the latest news, trends, and inspiration from the worlds of art, illustration, 3D modelling, game design, animation, and beyond.

Seasonal (around events)

Brand Impact Awards

Make an impression. Sign up to learn more about this prestigious award scheme, which celebrates the best of branding.

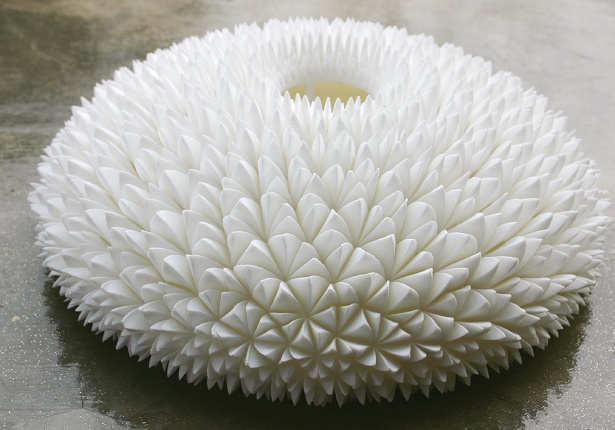

This is a recurrent point amongst those who have experimented with the medium: the equipment might be dropping in price, but it still isn’t a cheap process. South African sculptor Michaella Janse designs her pieces to be as small as possible to minimise costs, but there’s no room for error: “One small mistake in the mechanics could mean that the entire design doesn’t work as intended,” she warns.

It was during Janse’s postdoctoral fellowship in custom implant design in Bloemfontein in 2007 that she fell in love with 3D printing. The following year she set up a company exclusively dedicated to design for the medium: NOMILI. While the technology has developed, it’s the breadth of applications that she finds most exciting. “When I started, it was large brick-and-mortar 3D companies and universities that were manufacturing custom engineered parts and prototypes for product development,” she says. “The technology has become accessible to a wider audience, from hobbyists and artists to school children.” This is partly driven by the increasingly affordable hardware and software, she argues, but also by start-up companies like Shapeways and Ponoko, which provide manufacturing services to individuals.

As an effective blend of manufacturer and retailer, Shapeways processes sales, produces and ships the products, and handles customer service. “We’re trying to make high-quality 3D printing fast, cheap and accessible to designers and non-designers alike,” says the company’s marketing communications manager Carine Carmy. “The materials have become substantially better – at Shapeways we now have 25, including ceramic, steel and sterling silver – and we provide access to cutting-edge machines that cost north of $100,000,” she adds.

Christina Westbrook, 3D printing community service manager at Ponoko, echoes Johnny Kelly’s point that 3D printing is charged by volume, not complexity – in fact, you can even print several inter-linked moving parts in one go, as the machine can also print a second material in between the different components that dissolves away later.

“As long as it’s within the confines that make something printable, you can try out some interesting designs,” Westbrook explains. “Pieces can’t be too thin. The interior of a piece on the computer is like a shell for the material that will need to fill it – therefore the geometry needs to be clean inside a design. It might all sound like a foreign language, but once you start modelling it makes more sense,” she adds.

Janse emails her sculptures to a manufacturer, which then builds it up by fusing together thin layers of Nylon powder. “The object magically emerges from the heap of deposited powder,” she reveals. “A few days later, the completed sculptures arrive at my door. This is always a very tense moment. Will it come out as expected? All of the planning and designing focuses on this one moment of pure joy, when I hold a design that looks and functions exactly as I envisioned it.”

Based in Norfolk, Virginia, digital advertising and production studio Grow Interactive recently produced its first 3D printing-based project for Google. “3D printing is still in its infancy for sure,” reflects design director Joe Branton. “You can already do lots of amazing things with it, but I imagine that as materials and processes get developed further, you’ll be able to print almost anything you can think up.”

Grow’s creative director Drew Ungvarsky adds: “What you will find when you start to explore is that there are lots of options, each with strengths and weaknesses. One lesson is that the printing process is much slower than you’d expect. Depending on the size and complexity of the model, jobs can run for 15 hours or more, plus finishing time – even from what the company says is the fastest 3D printing technology on the market.”

So is 3D printing getting close to realising its full creative potential? “Nowhere near,” believes Brendan Dawes. “The stage that we’re at now is just the beginning. In the future, 3D printers might be as commonplace as a microwave. You’ll just buy physical objects online and print them in your house.”

Kelly agrees: “It’s absolutely impossible to say what the full creative potential of 3D printing might be,” he shrugs. “For me, the lure of animation has always been the possibility that you can create anything that your brain can dream up. 3D printing is exactly the same. Anything at all is possible, which is as exciting as it is daunting.”

Now check out these great examples of print in 3D at Creative Bloq!

Daily design news, reviews, how-tos and more, as picked by the editors.

The Creative Bloq team is made up of a group of art and design enthusiasts, and has changed and evolved since Creative Bloq began back in 2012. The current website team consists of eight full-time members of staff: Editor Georgia Coggan, Deputy Editor Rosie Hilder, Ecommerce Editor Beren Neale, Senior News Editor Daniel Piper, Editor, Digital Art and 3D Ian Dean, Tech Reviews Editor Erlingur Einarsson, Ecommerce Writer Beth Nicholls and Staff Writer Natalie Fear, as well as a roster of freelancers from around the world. The ImagineFX magazine team also pitch in, ensuring that content from leading digital art publication ImagineFX is represented on Creative Bloq.