Clever new tool makes 3D printing easier

Sign up to Creative Bloq's daily newsletter, which brings you the latest news and inspiration from the worlds of art, design and technology.

You are now subscribed

Your newsletter sign-up was successful

Want to add more newsletters?

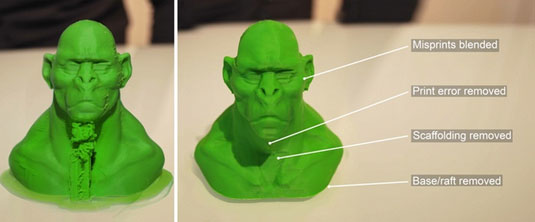

"Until you own a 3D printer, what you don’t realize is that removing supports and getting rid of printing errors can be frustrating and time-consuming," says Phil Newman of 3D printing startup 3D 2.0.

"We figured that if heat created a 3D print, then heat would be the best way to clean it up. And that’s how Retouch3D was born."

Recently launched on Kickstater, and having already surpassed its funding goal, Retouch3D is a hand-held heated tool with variable heat settings and interchangeable tips designed specifically for finishing 3D prints.

Its ergonomic handheld design helps you clean up 3D prints with the assistance of temperatures matched to the thermal properties of their printing material.

Retouch3D will be compatible with the mainstream materials used in 3D printing: PLA, ABS, and resin-based systems.

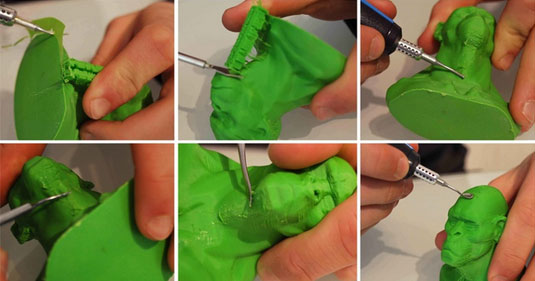

It combines a control system for accurate and efficient temperature control, with interchangeable tips designed for specific 3D retouching tasks, including:

- Removal of support material

- Refining layer imperfections and stringing

- Blending print surfaces and infill gaps

To account for future materials, Retouch3D’s fine temperature adjustment settings will allow users to increase or decrease heat by small increments.

Sign up to Creative Bloq's daily newsletter, which brings you the latest news and inspiration from the worlds of art, design and technology.

For early adopters, 3D 2.0 is offering the chance to become a beta tester. Beta testers will exclusively help the company finalize the design of the Retouch3D’s control system and interchangeable tips.

Backers can expect the first Retouch3D units to be available in early 2016, with full market availability following soon after. For more info, check out their Kickstarter page.

Like this? Read these!

- The world's fastest 3D printer revealed

- Hands-on review: Adobe After Effects CC

- How to build an app: try these great tutorials

Tom May is an award-winning journalist specialising in art, design, photography and technology. His latest book, The 50 Greatest Designers (Arcturus Publishing), was published this June. He's also author of Great TED Talks: Creativity (Pavilion Books). Tom was previously editor of Professional Photography magazine, associate editor at Creative Bloq, and deputy editor at net magazine.