Our Verdict

WeCreat has enhanced its already excellent Vision with several new features, making it an outstanding choice for creators and makers. The ability to swap laser modules means you can cut or engrave just about anything, and that lifting top is fantastic. The balance of power and detail is spot on, so no matter what kind of projects you work on, you’ll be set with the WeCreat Vision Pro. I’m thoroughly impressed.

For

- Fantastic form factor with auto riser

- Setting a project is easy with the aid of the camera

- Details are clear and fine

- It can cut thick materials

Against

- It’s one heavy machine

Why you can trust Creative Bloq

The maker/creator crowd is becoming better served every week by the looks of it. More gadgets, with new features, at more competitive prices, are a good thing. Competition is healthy for all, and the laser engraver market is a prime example of this.

Not all that long ago, they were bulky, industrial-looking units, most often unenclosed gantry systems, similar to older 3D printers. That was fine but they didn’t look attractive on the desk and they were costly, with far fewer possibilities for creative projects.

Things are very different now, with many developers looking to offer affordable, powerful and professional-looking machines that any creative would be happy to own. I tried WeCreat’s original Vision, along with a multitude of other laser cutters and engravers, so I was keen to see what the ‘Pro’ version had to offer – does it sit in our list of the best laser engravers out there?

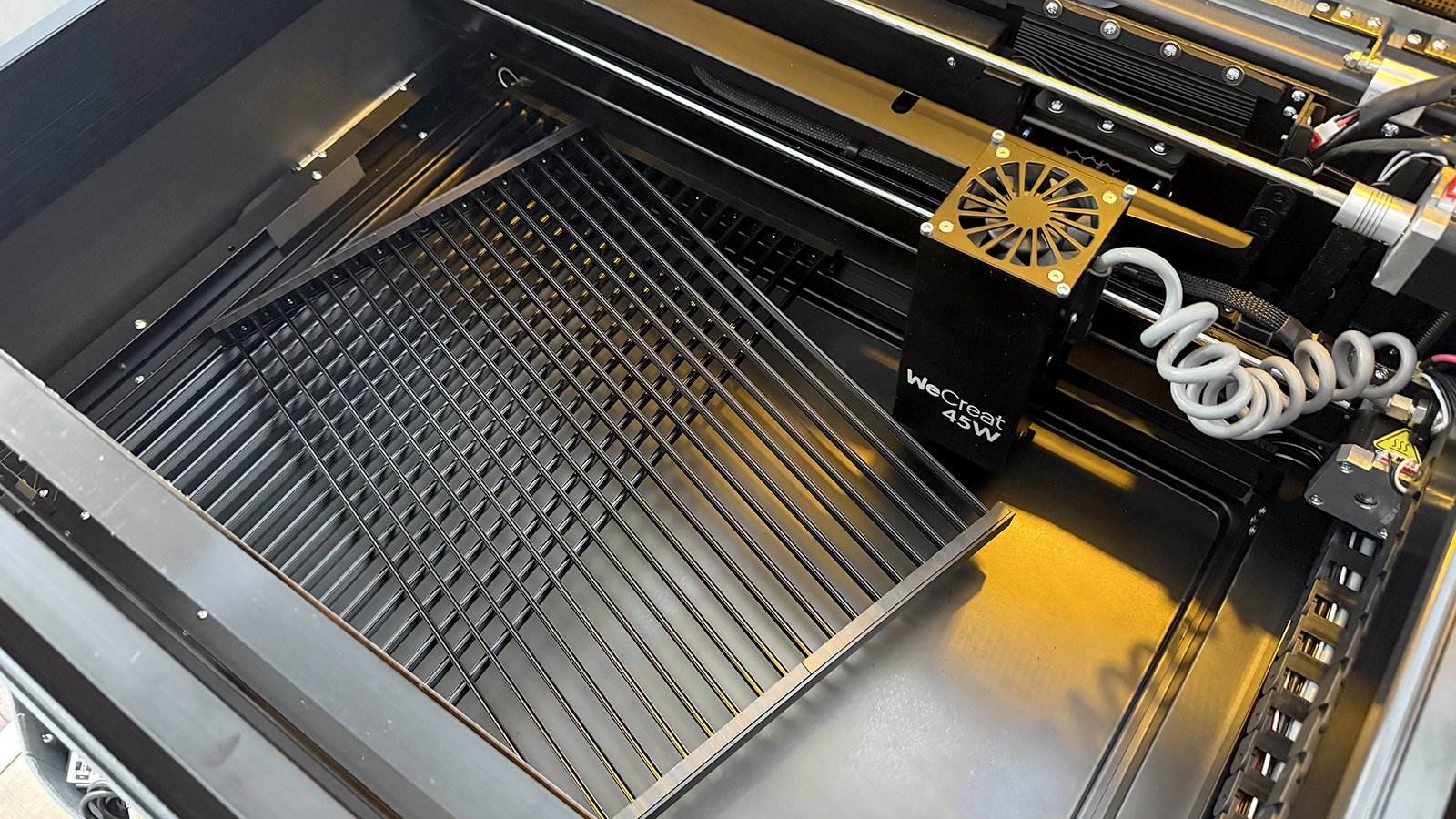

On paper, it sounds like a huge leap up, even though the form factor is pretty similar. A 45-watt diode laser, with an option for a 2-watt fibre module, better safety features and an internal camera. After running a good number of projects on the Vision Pro, I have some thoughts…

WeCreat Vision Pro review: What's in the box?

WeCreat Vision Pro: Setup and build quality

To get started takes just a few minutes. You’ll need to download the WeCreat MakeIt software, then add your device. Connecting via USB, this happened automatically, and from that point, you can set up a wifi connection and do away with the cables. Very useful.

Then it’s a simple matter of adding your design to the canvas, which can be anything from an imported photo or vector design, to AI-generated within the software, or a new design created directly in MakeIt.

Once you are happy with your project, you can tell the software which materials you’ll be using and line up your design with the materials. It’s all incredibly simple and fast to do, but I’ll expand more on that in the next section.

Daily design news, reviews, how-tos and more, as picked by the editors.

When you’re ready, you send the job to the Vision Pro, hit the big button at the front and let it do its thing.

WeCreat Vision Pro: Performance

I’m going to start this by comparing it to the previous, non ‘pro’, version. That was a good machine, but it had some issues that made it harder to live with. First and most impactful was the lack of an internal camera. Lining materials up with pins is totally possible, but the camera in the Pro makes this a breeze. Take a snapshot of the material on the bed and simply move your design into place. It’s a joy to do, speeds up the whole process, while also giving you confidence that everything is in its right place. This alone makes the Vision Pro a worthy purchase.

Then there is the cutting and engraving ability, the main purpose for even considering a machine like this. There is a rather wide range of results that can be obtained, and it’s key to work out the best settings before you start, and luckily, WeCreat has made this process as easy as can be. In the MakeIt software, once you have defined your materials, you are presented with a visual indicator of what different settings will look like on your chosen material. This could save hours of fiddling with parameters, as well as money in test materials. I found this to be pretty accurate and, when I used my preference for my own project, got exactly what I was after.

The actual results are very impressive, thanks to a number of factors. Firstly, a 45-watt laser module, which is plenty powerful enough for even tough projects. It can cut 25mm through wood and 20mm through acrylic. Far more than other machines I’ve used.

Then there is the IR module. At 2 watts, it may not sound like all that much, but for engraving metals, it is just right. It produces excellent clarity and detail and is capable of very fine work. Better yet is that if you do a little testing, you can coax all manner of colours out of it. Metals tend to react differently to varying settings, making it easy to change the finish of your engraving, and the material preview in the MakeIt software helps here, too.

I’ve used many styles of laser, and while a little larger than some (see my review of the XTool F1 Ultra) dual laser devices, there’s a big benefit to the gantry style. When cutting with a lensed machine, the laser stays in place, with mirrors used to guide the beam. This keeps the machine compact, but it does mean that the further from the Y axis of the laser, the more angled a cut will be. If you’re only doing light engraving, this isn’t an issue, but as soon as you work with deeper cuts, the angles become more pronounced.

The Vision Pro negates that worry, as the laser remains perpendicular to the material at every point. You could very easily cut a jigsaw an inch thick with full confidence that it will work perfectly.

Lasers are powerful bits of kit, so safety is high on the agenda, and it’s great to see WeCreat take this seriously. The air assist, while more beneficial to clean cuts, does prevent some heat buildup, but it doesn’t end there. There is good ventilation via the exhaust, and I’d highly recommend getting a fan-assisted filter, rather than venting out of a door or window.

The full metal enclosure provides a level of security, too, and should you need to, you can pause or cancel a job directly from the front panel.

One issue I’ve encountered regularly with other machines is material height. Typically, you’ll need a riser platform of some kind to allow enough clearance for the material below the laser. The Vision Pro has a very clever autolift feature, which you’ll notice on first powering it up. The entire gantry and module lift. This motorised upper half will lower to focus on any material placed under i,t and it works very well. It’s a joy to not have to manhandle a fairly heavy piece of machinery to get a piece of wood i,n and props to Wecreat for this system. I really appreciate this quality of experience benefit. Better yet, the crumb tray and grids stay in place, meaning even less hassle.

On top of this, the lifting mechanism allows for a really good rotary add-on. I find these a bit hit or miss, but this one seems to work really well. A cable and a few screws fix it in place, and you’re ready to go. The software recognises it and you even get a 3D preview. Lining a project is simple with the camera and, something I really like and mentioned earlier, is that the chuck on it can grip internally and externally, meaning designs can cover more surface area of your tumbler or glass.

Who is the WeCreat Vision Pro for?

• Maker spaces and creatives looking to cut and engrave a wide range of materials

Buy it if

- A simple workflow is needed

- High detail results are important

Don't buy it if

- You don’t have a suitably sturdy worktop for it

out of 10

WeCreat has enhanced its already excellent Vision with several new features, making it an outstanding choice for creators and makers. The ability to swap laser modules means you can cut or engrave just about anything, and that lifting top is fantastic. The balance of power and detail is spot on, so no matter what kind of projects you work on, you’ll be set with the WeCreat Vision Pro. I’m thoroughly impressed.

Rob Redman is the editor of ImagineFX magazines and former editor of 3D World magazine. Rob has a background in animation, visual effects, and photography.

You must confirm your public display name before commenting

Please logout and then login again, you will then be prompted to enter your display name.